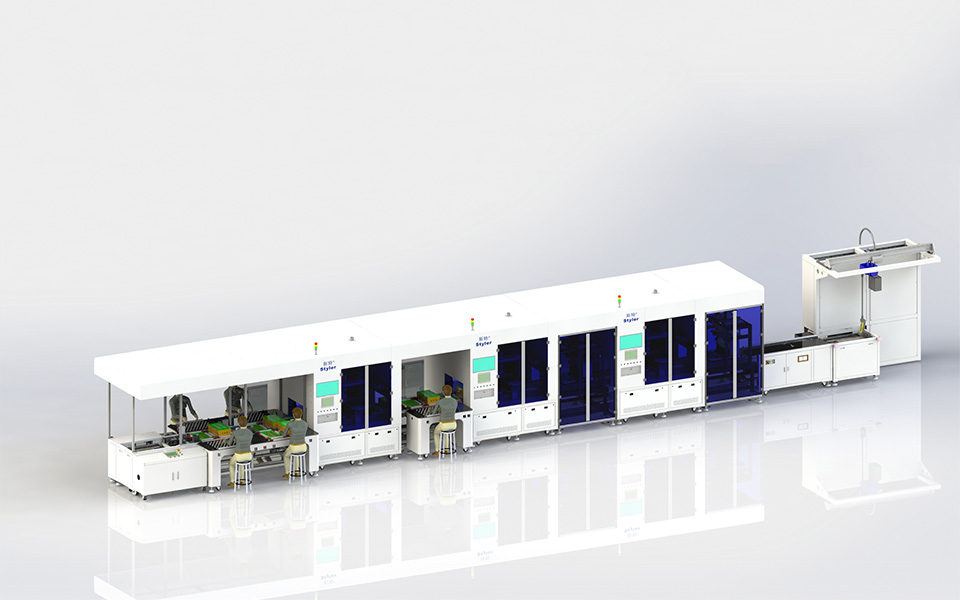

In the field of new energy applications, battery assembly is a critical process. In order to meet the growing market demand, Styler has launched the most advanced Battery assembly wiring Specially optimized for spot welding operations, ensuring excellent product quality and high efficiency.

Flexible design to meet different needs

Styler's battery assembly wiring has a highly flexible design that can easily adapt to the production requirements of different battery pack models. Whether it's different unit sizes or a range of brackets and connector fixtures, our equipment can be quickly adjusted to adapt to different production tasks. This flexibility greatly reduces the adjustment time of the production line, ensuring continuous and efficient production.

Human machine integration improves quality and efficiency

At Styler, we emphasize the importance of human-machine integration throughout the entire production process. By optimizing each step, our assembly line not only ensures high-quality output at every stage, but also greatly improves production efficiency. The seamless integration of human and machine operations makes the production process smoother, allowing for flexible switching between humans and machines as needed to meet various production needs.

Independence and modular design

Styler's assembly line adopts a modular design with independent machines, allowing each device to operate autonomously. This ensures flexibility in production - when expansion or adjustment is needed, additional or replacement equipment can be easily integrated without the need for extensive modifications to the entire production line. This independence provides our clients with great convenience and flexibility.

RFID transmission and data management

To ensure the accuracy of data during the production process,Styler's assembly line RFID transmission system is adopted. The data of each workstation can be recorded in real time, so that production data can be uploaded in a timely manner and precise data management can be carried out for each workstation. This meticulous data processing provides customers with clear insights into each stage of production, ensuring transparency and traceability.

Easy to adjust production process

Styler's assembly line design emphasizes the adjustability of craftsmanship. According to production needs, the process can be modified at any time, and instant production can be achieved through simple connections. This design not only improves the adaptability of the production line, but also ensures the flexibility of production, meeting the dynamic needs of customers.

Professional technical support and after-sales service

In addition to providing high-performance assembly line equipment, Styler also offers comprehensive technical support and after-sales service. Our expert team is always ready to assist clients in resolving any production issues, ensuring smooth and efficient operations.

For anyone interested in battery assembly wiring, please feel free to contact Styler at any time. We are committed to providing you with optimal solutions to help your new energy business thrive. For more information about our comprehensive spot welding equipment and laser welding equipment services, please visit http://www.dgcd-jg.com/ Or contact us at 13580722659.

Dongguan Chuangde Laser Intelligent Technology Co., Ltd

One stop laser welding solution service provider